Zucchetti Digital Supply Chain is the unique digital solution for the holistic management of the supply chain: production, logistics, transportation, distribution, and after-sales.

Zucchetti Digital Supply Chain's softwares

A symphony of innovative, high value-added solutions.

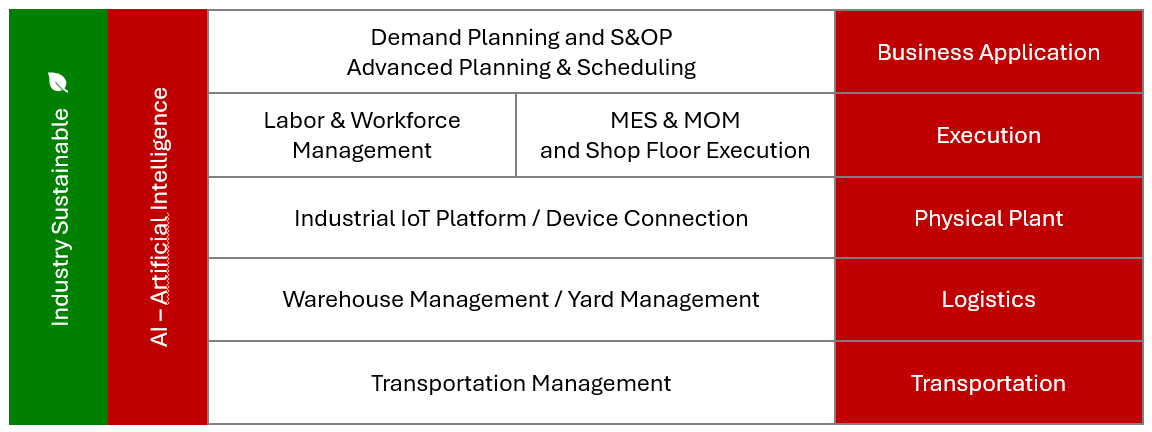

Managing and orchestrating activities across the entire supply chain is a complex challenge, with needs and technologies that vary significantly from one process to another.

The extensive experience of Zucchetti Digital Supply Chain stems from the deep expertise of each company involved, which has developed high-performance, cutting-edge software to meet the diverse and concrete needs of its customers.

Software to power an optimized and sustainable supply chain

From the factory onward, the software solutions make it possible to optimize the inbound flow of raw materials through sophisticated Demand Planning and Sales & Operations Planning tools.

With Advanced Planning & Scheduling software, companies can rapidly and continuously simulate multiple finite-capacity production scenarios, gaining immediate visibility into the impacts on the production plan.

Once production plans are defined, execution begins through integration with awm, the Workforce and Labor Management software. It identifies the appropriate human resources for each function and production cycle, taking into account workloads, skills, and specializations. The setup of production lines is then managed through integration with the MES or MOM (Manufacturing Operations Management) system.

The MES (Manufacturing Execution System) or Advanced Planning software also integrates with the WMS, triggering the warehouse movements required to supply raw materials and components to the production line.

Once the product is completed, the WMS (Warehouse Management System) takes charge of the finished goods and manages all storage, replenishment, picking, packing, and shipping activities within the warehouse.

Inbound and outbound process automation is ensured through Yard Management System software, which reduces driver waiting times in yards by planning vehicle arrivals based on the logistics capacity of each plant, avoiding queues and inefficiencies.

Multilingual kiosks and license plate recognition cameras—or other identification systems—further enhance reception desk operations, enabling fast, real-time communication with all parties involved in the arrival or departure of a truck.

Through integration with the TMS (Transportation Management System), transport planning, route selection, and carrier evaluation are managed to ensure optimal and efficient flows.

Carbon footprint calculation also allows companies to assess the environmental impact of transportation and make sustainability-oriented decisions.

Proof of delivery and transport cost control enable companies to provide customers with accurate, timely service—without compromising their margins.

Artificial intelligence systems optimize all flows along the supply chain, managing anomalies and proposing solutions to enhance the process, making it more efficient and sustainable.

Every phase of the supply chain is continuously monitored through reports and statistics that not only ensure control but also support continuous improvement. This is achieved through an orchestrated, end-to-end perspective that provides data for simulations designed to harmonize the entire production and distribution ecosystem for greater efficiency and sustainability.

The specialized software solutions of the Zucchetti Digital Supply Chain

The SMA.I.L:) SMART INTEGRATED LOGISTICS software platform enables the management of logistics, warehouse operations, yard activities, transportation, shipment certification, and cost control. It integrates:

- WMS Replica – Warehouse Management System

- YMS Replica – Yard Management System

- TMS Replica – Transportation Operation System for manufacturing and distribution companies

- TMS SIMA – Transportation Management System for transport and forwarding companies

Cybertec’s software for Advanced Production Planning and Scheduling, suitable for any manufacturing environment.

It includes:

- Demand Planning

- S&OP (Sales & Operations Planning)

- Supply Chain Planning

- Advanced Planning & Scheduling

It is the platform that enables digitalization and real-time control of the entire production process and includes:

- Manufacturing Execution System (MES)

- Manufacturing Operations Management (MOM)

- Industrial IoT Platform

- Device Connectivity

It is the software for workforce planning based on:

- Skill Matrix

- Safety Management

- Shift scheduling

- Absence Management

- Performance Monitoring and Analytics

Vertical solutions for a more sustainable supply chain

Vertical solutions for a more sustainable supply chain

The Zucchetti Digital Supply Chain portfolio is complemented by specialized vertical software, designed to meet the unique needs of specific industries and further enhance operational efficiency.

Integrated with the core solutions, this software ensures optimized and tailored supply chain management.

- Z-Maintenance Asset Management: manages and optimizes the lifecycle of company assets, ensuring efficient preventive and corrective maintenance.

- Z-Energy Energy Management: monitors and optimizes your company’s energy consumption to reduce costs and improve environmental sustainability.

- Z-Track for Logistics Management: a new centralized platform that collects, processes, and shares vast amounts of information with multiple providers regarding vehicle location, traceability, and availability.

- Traxal: a vertical MES solution specifically designed for the food industry, ensuring traceability, compliance, and production process optimization.

- Optima: software dedicated to glass manufacturing, optimizing production management to improve efficiency and reduce waste.

Information request

For any questions or information about our products or services, please do not hesitate to contact us.

Share this content on: